It's recommended that PCB design engineers review their generated Gerber files before sending the board to be produced. Once the design and layout are finalized for production, a designer will export the printed circuit design information in one of the above formats alongside other required production files. It includes important information, such as object functions like pad type, the layer function of the file, locations of impedance-controlled traces, and much more.

This version combines apertures, configuration parameters, XY coordinates, and draw & flash commands into one single file.

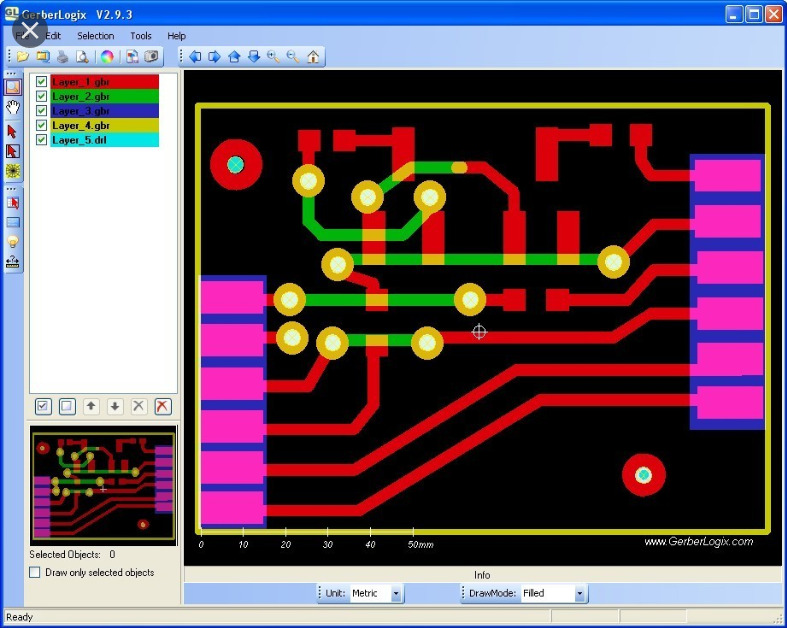

#Gerber file viewer software#

RS-274-X - This extended Gerber format is widely used by almost all design software programs for PCB production.These files contain only the XY coordinate locations and the draw & flash commands. RS-274-D - This is the first and original version of the Gerber file format, and it has now been replaced by RS-274-X.The following are the three currently existing versions of Gerber file formats: These 2D images are used to create stencils, fixtures, and any other tooling required to fabricate a bare PCB. A Gerber file looks just like an image of a particular PCB layer a Gerber file encodes this image of each layer as an open ASCII vector format, giving a 2D representation of each layer in a PCB. The most common file format is Gerber files.Ī Gerber file consists of all the crucial information, such as copper content, hole locations, assembly information, silkscreen, etc., required to fabricate a bare PCB. Once designers have created the PCB layout in their design application, the software converts the design into manufacturing data.

Gerber files are the software files that PCB designers give to manufacturers for the production of a PCB. Currently, the rights to the Gerber file format are owned by UCAMCO. Developed initially by Gerber Scientific, a company founded by Joseph Gerber, Gerber files have now become the standard file format used to fabricate a bare PCB.

0 kommentar(er)

0 kommentar(er)